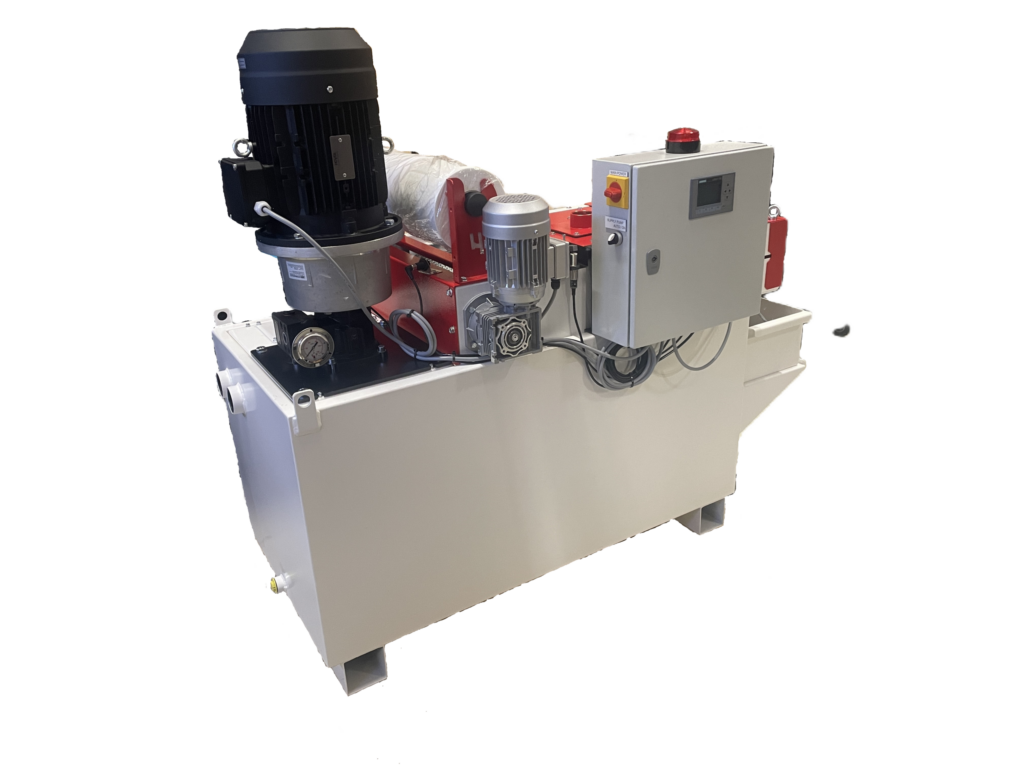

High pressure system

The PLUS high pressure system consists of a 400-liter coolant tank, a fabric filtration unit and a 40 or 70 bar high-pressure pump

- PLUS is a ready-to-connect system for machine tools when increased pressure and coolant capacity are required to improve machining efficiency. In addition, it can be used solely for coolant filtration by circulating the fluid through the system even when the high-pressure pump is not in operation.

- The system is available in two versions: BASIC and COAX. Both versions feature control implemented with a Siemens LOGO! micro PLC and are equipped with a diagnostic display. The diagnostic display makes it easy for the user to identify the cause of a fault condition and take corrective action.

- The system always includes coolant level monitoring to prevent the high-pressure pump from running dry. The end of the filter fabric is also monitored by a dedicated sensor.

- The PLUS system is connected to the machine tool via I/O interfaces, allowing it to operate under machine tool control. The COAX version additionally enables limiting the high-pressure pump pressure to predefined set values, which are activated via the machine tool’s M-codes.

- A magnetic filter on top of the filter unit is available

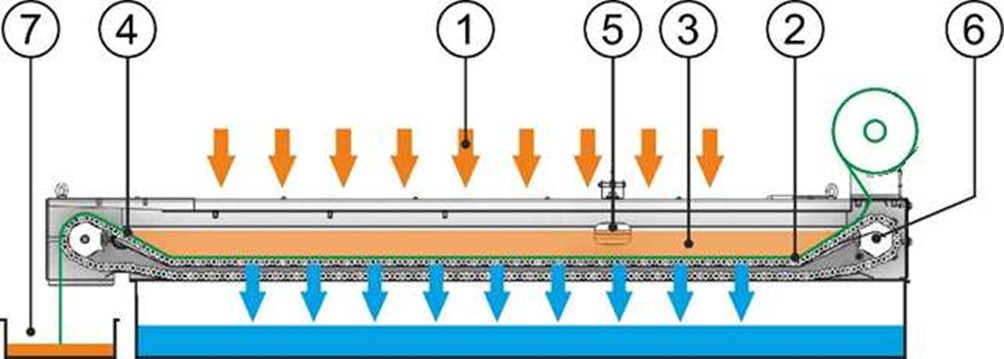

Working principle

Coolant filter is designed to filter coolant having a maximum viscosity of 20°cSt at 40°C. The maximum flow rate of the coolant is 70 l/min (1 cSt). Filter fabrics are available with filtration ratings of 25, 35, or 50 µm. The coolant to be filtered (1) is pumped from the machine tool´s coolant tank onto the filter fabric (2) forming a coolant layer on it (3). The coolant is filtered through the filter so that the dirt particles remain in it (4) and the clean coolant flows into the tank. A layer of sludge slowly accumulates on top of the filter, causing the permeability of the fabric to decrease and the level of the coolant on top of it to rise. Then the level sensor (5) starts the conveyor (6) that transports the filter fabric, which in turn pulls out the clean fabric and transfers the sludge and dirty fabric to its own container (7)

BASIC system features:

- Possibility to circulate coolant with the supply pump through the filter even when the high-pressure pump is not in use.

- The control box can be installed on either side of the unit.

- The tank has two pairs of connections for the return hoses, so they can be installed on the end or on the side of the tank as needed. Unused connections must be plugged (plugs included).

Contents of the BASIC system:

- 40 or 70 bar high-pressure pump

- Easyband 50 coolant filtration unit

- 400l coolant tank

- ACP-251A supply pump (to be installed in the coolant tank of the machine tool)

- 5 m coolant supply hose

- 2 pcs 3 m return hose

- Control box with Siemens LOGO! and diagnostic display

- Operating voltage 3 x 400V

- Option to install high-pressure pump and control box as mirror image

- Option to install the discharge hoses on two different sides of the tank

- Diagnostics display shows clearly the potential cause of the error

- Option of recycling coolant through the filtration unit even when the high-pressure pump is not running- bypass switch

- The Siemens LOGO! enables:

- Monitoring for fabric running out

- Monitoring of the coolant level in the tank, preventing the pump from running dry

- Warning light in case of equipment error

- Different levels of warning and alarm signals for the machine tool

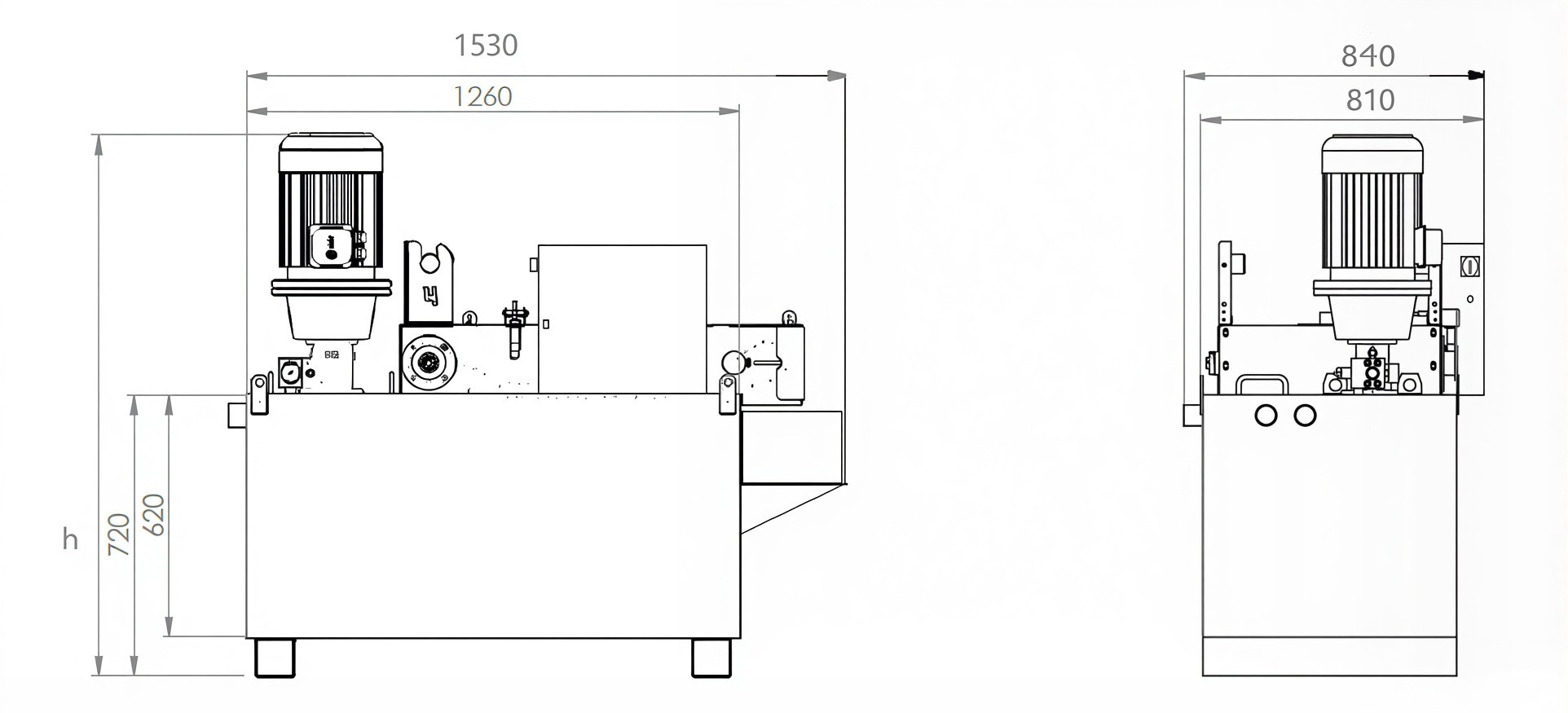

Specifications and measurents

| High pressure pump | H |

|---|---|

| 40bar | 1430 |

| 70bar | 1445 |

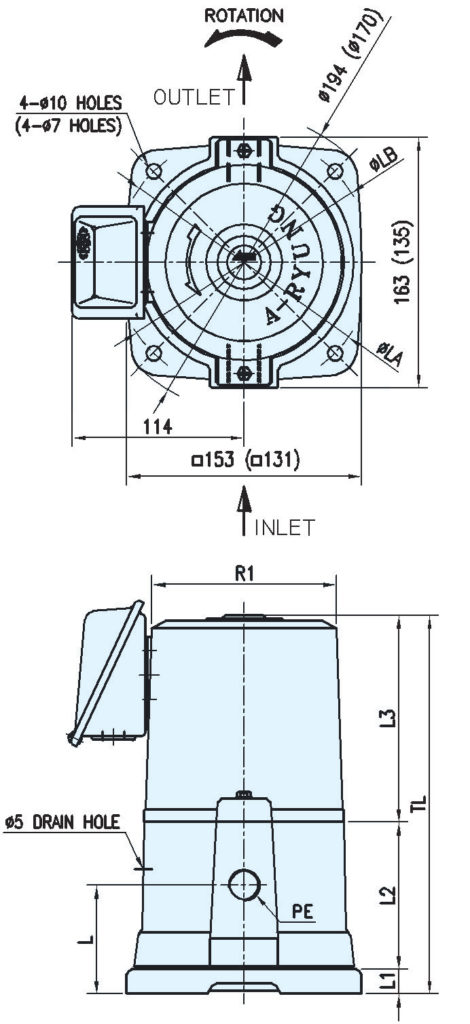

ACP-251A

| Type | L | L1 | L2 | L3 | TL | ØR1 | ØLA | ØLB | PE |

|---|---|---|---|---|---|---|---|---|---|

| ACP-251A | 71 | 16 | 96 | 135 | 247 | 120 | 160 (167) | 170 (170) | 2-PS 3/4″ |

| Type | Discharge volume (l/min) | Pressure (bar) | Outlet (PS) | Power (kW) | Frequency (Hz) | Voltage 3-phase (V) | Current (A) | Weight (kg) |

|---|---|---|---|---|---|---|---|---|

| ACP-251A | 85 | 0,4 | 3/4″ | 0,25 | 50 | 200/380 | 1,50/0,87 | 13,0 |

PWO 40/70bar

| Type | a (mm) | b (mm) | c (mm) |

|---|---|---|---|

| 40 bar | 218 | 580 | 157 |

| 70 bar | 258 | 705 | 198 |

| Type | Output (kW) | Current (A) | Voltage 3-phase (V) | Weight (kg) | Discharge volume 1 cSt (l/min) | Discharge volume 20 cSt (l/min) | Cable entry |

|---|---|---|---|---|---|---|---|

| 40 bar | 5,5 | 17,2/9,93 | 200/400 | 66 | 41,9 | 46,3 | 1,5 x M20 |

| 70 bar | 7,5 | 13,2 | 400 | 74 | 38,3 | 44,8 | 1,5 x M25 |