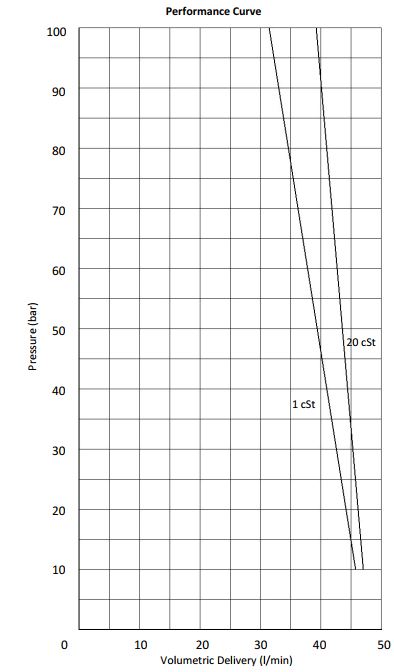

(40 bar and 70 bar)

Applications:

- High pressure pumps with low volumetric delivery

- Cutting, turning milling, boring, grinding and similar applications of machine tools

- Especially used for deep hole boring operations due to the high pressure up to 100 bar

- Pumping cutting/cooling fluids in circulation systems

Fluid Specifications:

- Coolants

- Cutting oils

- Grinding oil

- Emulsions (minimum 5% oil)

- Thermal oils (contact for detailed information)

- Kinematic viscosity 1…400 mm2 /s (contact for higher viscosities)

Materials:

Spindles: high performance steel, hardened steel

Pump body: Cast iron – DIN GG 26, specially heat treated

Discharge casing: Cast iron – DIN GG 26

Housing: Aluminium

Mechanical seal: SiC-SiC-Viton

O-ring: Viton

suction pipe: Steel

Motor:

IE2 3-phase induction motor

2-pole, 2900 RPM

Protection degree, IP 55

Insulation class F

NOTE! The used fluid must be filtered through at least a 50 micron filter

| Type | Output (kW) | Current (A) | Voltage 3-phase (V) | Weight (kg) | Discharge volume 1 cSt (l/min) | Discharge volume 20 cSt (l/min) | Cable entry |

|---|---|---|---|---|---|---|---|

| 40 bar | 5,5 | 17,2/9,93 | 200/400 | 66 | 41,9 | 46,3 | 1,5 x M20 |

| 70 bar | 7,5 | 13,2 | 400 | 74 | 38,3 | 44,8 | 1,5 x M25 |

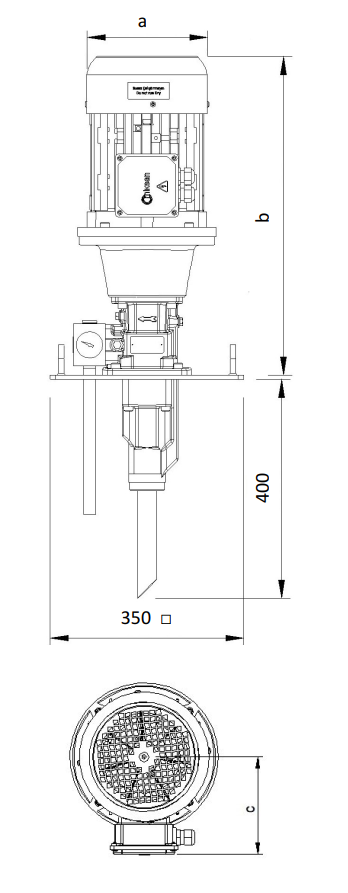

| Type | Dimension a (mm) | Dimension b (mm) | Dimension c (mm) |

|---|---|---|---|

| 40 bar | 258 | 690 | 198 |

| 70 bar | 258 | 705 | 198 |

With 40 or 70bar pump

With 20bar pump